UV Resistance in Sewing Threads

Contents

How does ultra-violet light affect sewing thread?

Radiation from the sun

Ultra-violet radiation

Exposure of sewing thread to sunlight

Protection of sewing thread by glass

Factors affecting UV reaching the earth's surface

Factors affecting UV degradation

How does ultra-violet light affect sewing thread?

This is due to the ever increasing standards for the final product in terms of colour fastness and seam strength in exposed conditions. To determine the resistance of a particular thread against UV light degradation, the thread can be tested. However, there is not one standard test for this, instead there are many different tests for UV resistance all of which will give different results. The comparison therefore, must be a relative one. To understand this, we must look at what UV light is and where it comes from.

Radiation from the sun

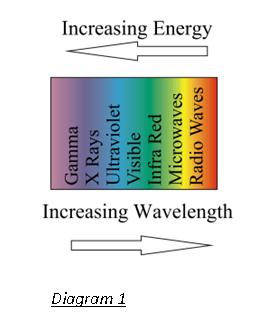

Ultra-violet radiation comes from the sun. It is just one part of a spectrum of electromagnetic radiation which is emitted by the sun. Diagram 1 shows the full spectrum of electromagnetic radiation. As the wavelength of radiation decreases, the corresponding energy increases:

Electromagnetic Radiation

E = hc

λ

E= Energy

h= Planck's Constant

c= Speed of Light

λ = Wavelength measured in nanometres (nm)

Ultra-violet radiation

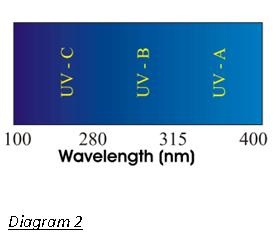

The region of ultra-violet radiation extends down from 400 to 100 nm and is subdivided by the International Commission of Illumination (CIE) into 3 bands: UV A, UVB, and UV C (Diagram 2).

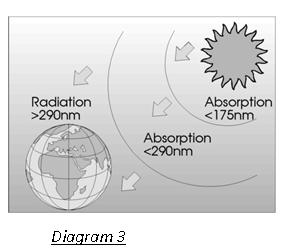

Radiation below 175nm is filtered out due to absorption by oxygen in the layers of the atmosphere above 60miles. Radiation between 175nm and 290nm is filtered out by the ozone layer of the stratosphere and by water vapour and carbon dioxide. The minimum wavelength reaching the earth's surface is 290nm (Diagram 3).

Exposure of sewing thread to sunlight

UV degradation of sewing threads is concerned with the physical and chemical changes resulting from irradiation of the base polymers by ultra violet or visible light. The energy absorbed leads to degradation of the polymeric chain and a loss of strength in the sewing thread. It also attacks the dyes concerned leading to fading or spotting of the thread colour.

Protection of sewing threads by glass

Windows containing ordinary glass filter out high frequency radiation between 290 and 320nm, this provides partial UV protection. Laminated glass is used in most car windscreens. It provides much greater protection than the toughened glass normally used in side and rear windows by filtering out virtually all radiation wavelengths below 380nm. Tinted automotive glass, although designed to absorb infra-red radiation, also absorbs ultra violet radiation below 340nm.

Factors affecting UV reaching the earth's surface

The intensity and wavelength of UV radiation reaching the earth's surface is affected by many factors (Diagram 4). The cloud cover influences the amount of atmospheric filtering and therefore influences the minimum wavelength of light reaching the earth's surface.

The intensity of total radiation and its spectral distribution are affected by the geographic latitude and by the daily and seasonal positions of the sun. When the sun is directly overhead, sunlight passes through a minimum amount of air on its way to the earth's surface and so there is minimum atmospheric filtering of UV.

When the sun is lower in the sky, sunlight travels through a greater mass of air and so atmospheric absorption of UV is increased. As well as intensity and wavelength of UV radiation, oxides of nitrogen and sulphur are discharged into the atmosphere as pollutants from the combustion of fossil fuels. The weathering of textiles by these oxides is combination of oxidation and hydrolysis. The process is catalysed by the acids produced as a result of the reaction of these gases with atmospheric moisture.

All polymers degrade at different rates. UV degradation results in a gradual deterioration of the threads properties. Thread fibres are particularly vulnerable to degrading agencies because of their geometric form (high area to volume ratio).

UV degradation results in:

- Strength reduction

- Reduction in abrasion resistance

- Fading of colours in thread

Factors affecting UV degradation

UV degradation is influenced by many factors:

1) Fibre Type

a) Manufacturing conditions

b) Thermal history of the polymer

c) Impurities

2) Additives

Many additives are available e.g. copper compounds, UV absorbers, and anti-oxidants are effective in slowing down the degradation process. Additives such as UV absorbers have much more effect if they are added to the raw yarn during spinning rather than afterwards e.g. during dyeing as applying here can allow it free to migrate to other components after stitching, negating its effect.

3) Dyestuffs

Good selective use of dyestuffs minimizes degradation as dyes can act as photo catalysers or photo stabilizers. Most degrees of light fastness can be met by using the appropriate dyes such as premet dyes for automotive.

4) Wavelength

The lower the wavelength, the higher the energy of radiation available to degrade the thread.

5) Intensity

The amount of radiation which reaches the source through the atmosphere, affected by:

a) Level of sun

b) Cloud cover

c) Pollution

Testing of threads for UV resistance

The testing of any thread for UV resistance has to take into account the following conditions:

a) Wavelength

b) Intensity

c) Humidity

d) Temperature

e) Duration of Exposure

Variations in any of these conditions will have an effect on the UV degradation of the thread no matter what type of thread used or what UV protection it has. These conditions will effect:

a) The degradation of the thread

b) The level of colour fastness

However, threads can be produced, which have a high resistance to UV degradation by careful processing, also by including chemical UV inhibitors during its manufacture, and by using selective dyestuffs to produce good levels of colour fastness. Most UV tests are carried out at a wavelength value between 400nm and 300nm, the lower the wavelength, the more severe the test.

When specifying a thread for UV resistance two things must be known:

1) The standard which the thread must achieve.

2) The conditions under which the standard must be achieved.

Once these are known, the development of a thread to meet these requirements can be carried out.

Comment: Just because a thread meets a set standard under one set of conditions does not mean it will meet it under different conditions, i.e. if you decrease the wavelength of the light source then the resultant higher energy will degrade the thread to a higher degree and the thread may not meet the agreed standard. Overall, if threads are to be tested for UV resistance, they should be tested on a relative basis, i.e. relative to a standard OR to other threads under the SAME conditions. Coats supply Coats Dabond thread for outdoor end uses and Coats Neophil and Coats Gral for high UV resistant automotive end use applications.